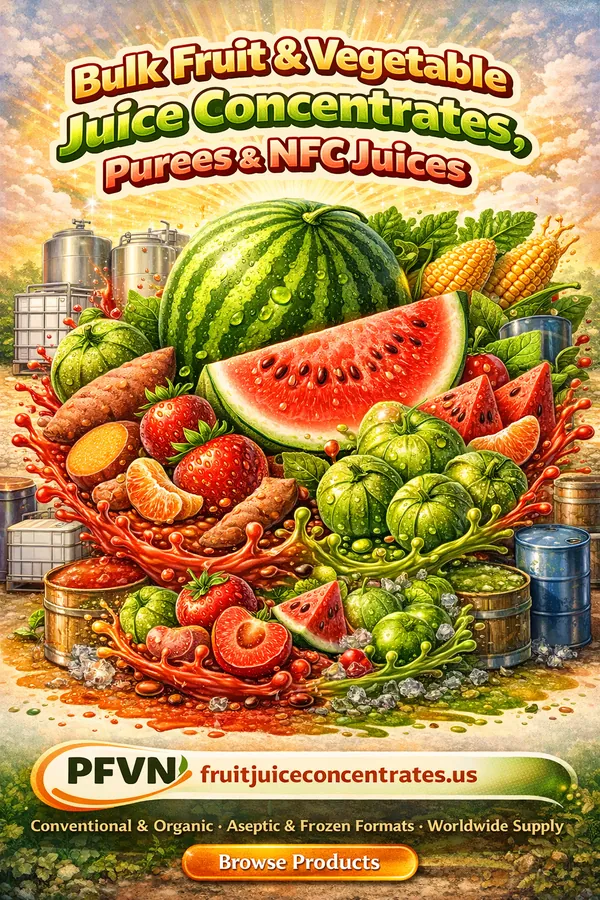

Bulk Fruit & Vegetable Juice Concentrates, Purees & NFC Juices

PFVN, Inc. cooperates with leading processors in the USA and globally to supply industrial fruit and vegetable ingredients for professional manufacturing. If you’re purchasing for beverage, dairy, bakery, confectionery, sauces, brewing/fermentation, spirits/RTD, baby food, nutrition, or pet food, we help you choose the right format, confirm the right specifications, and align the right packaging and lane (ambient, chilled, or frozen).

We keep the catalog simple: one page per fruit/vegetable, with all available formats covered on that page.

Browse products Compare formats Explore applications

New to bulk sourcing? Jump to How to specify for a quick buyer checklist.